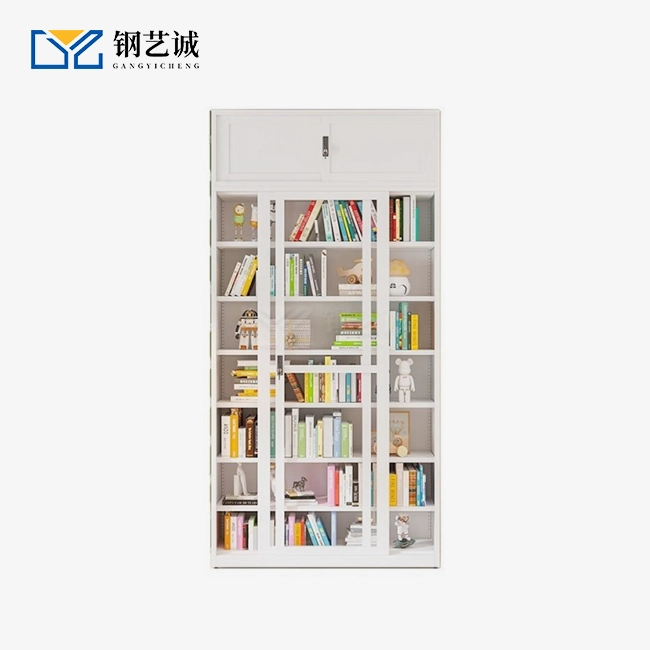

Manufacturing environments demand smart storage solutions that maximize efficiency while maintaining safety standards. White Metal Combination Storage Cabinets have emerged as essential equipment across production facilities worldwide, offering versatile organization options for tools, components, and safety gear. These steel storage organizers provide reliable containment systems that adapt to diverse manufacturing needs. Their powder coated metal construction ensures long-term durability in demanding industrial settings. Understanding these applications helps purchasing managers optimize their facility operations while meeting regulatory requirements.

Essential Tool Organization in Production Lines

Production lines require immediate access to precision tools and measuring equipment. Metal storage units positioned strategically along assembly areas eliminate wasted motion and reduce downtime. Lockable storage boxes protect expensive calibration instruments from unauthorized access and environmental contamination.

Manufacturing teams benefit from organized tool placement that follows 5S methodology principles. Each compartment accommodates specific instruments, creating visual management systems that prevent tool loss. Workers locate required items quickly, maintaining production rhythm without interruptions.

Quality control departments utilize these systems for gauge storage and measurement device organization. The secure storage locker design protects sensitive equipment from temperature fluctuations and dust exposure. This approach reduces calibration frequency and extends tool lifespan significantly.

Personal Protective Equipment Management

Maintenance and distribution of personal protective equipment (PPE) must be carried out in a systematic manner. Headgear, safety glasses, gloves, and other respiratory protection equipment can all be stored in industrial storage cabinets, which are specifically designed for this purpose. The multi-tiered storage rack arrangement is able to support a wide range of personal protective equipment (PPE) sizes and types.

Employees are provided with storage compartments that are specifically designated for their personal safety gear. In addition to ensuring that hygiene standards are met, this individual accountability system guarantees that the necessary equipment is available. When goods regularly occupy positions that have been specified for them, routine inspections become more efficient, especially with the use of a White Metal Combination Storage Cabinet.

The location of centralized cabinets in close proximity to high-risk work areas is advantageous for emergency response equipment. The availability of first aid supplies, emergency eyewash stations, and materials for spill containment cannot be compromised in the event of a severe crisis. While maintaining vital safety resources, the long-lasting storage solution is able to survive the extreme conditions that are present in production environments.

Chemical and Hazardous Material Storage

Chemical storage regulations demand specialized containment systems for manufacturing operations. Heavy-duty storage cabinets, such as the White Metal Combination Storage Cabinet, meet OSHA requirements for flammable liquid storage and chemical segregation protocols. The steel construction provides fire resistance while preventing unauthorized access to dangerous substances.

Secondary containment features protect facilities from accidental spills and chemical reactions. Interior shelving accommodates various container sizes while maintaining proper separation distances. Ventilation compatibility ensures safe storage conditions for reactive materials and volatile compounds.

Inventory tracking becomes simplified through organized chemical placement systems. Each storage cabinet with doors maintains clear labeling and safety data sheet access. This systematic approach reduces regulatory violations while protecting worker health and environmental safety.

Component and Parts Inventory Management

Manufacturing operations depend on organized component storage for efficient production flow. Modular storage systems accommodate fasteners, electronic components, and mechanical parts across multiple product lines. The compact storage cabinet design maximizes floor space utilization in cramped production areas.

Just-in-time manufacturing benefits from strategic parts placement near assembly stations. Workers access required components without leaving their work areas, maintaining production tempo and quality standards. This proximity reduces handling damage and inventory shrinkage significantly.

Quality control improves through segregated storage of approved and rejected parts. Color-coded cabinet systems prevent mixing of conforming and non-conforming materials. This visual management approach reduces manufacturing errors and customer complaints substantially.

Maintenance Supply Organization

The storage of lubricants, filters, and replacement parts must be arranged in order to fulfill the requirements of preventive maintenance plans. Maintenance supplies can be stored in close proximity to the locations of the equipment using space-saving storage solutions, which in turn reduces the amount of time needed for repairs and routine service.

Maintenance teams benefit from standardized supply organization across multiple facility locations. Stackable storage units, such as the White Metal Combination Storage Cabinet, create consistent layouts that improve technician efficiency and reduce training requirements. Emergency repair supplies remain accessible during equipment breakdowns.

Inventory control improves through dedicated maintenance supply cabinets that track usage patterns and reorder points. This systematic approach prevents stockouts while minimizing excess inventory carrying costs. Maintenance schedules become more reliable with consistent supply availability.

Documentation and Record Storage

Manufacturing documentation requires protection from environmental hazards while maintaining accessibility for quality audits. Office filing cabinets designed for industrial environments protect work instructions, inspection records, and regulatory documentation from moisture and contamination.

ISO certification requirements mandate organized record storage systems that facilitate auditor access and document retrieval. The cabinet with shelves configuration accommodates various document sizes and formats efficiently. Fire protection features preserve critical manufacturing records during emergency situations.

Digital backup systems complement physical document storage through organized filing systems. Workers locate required documentation quickly during production troubleshooting and quality investigations. This dual approach ensures information availability regardless of system failures or power outages.

Benefits of Manufacturing Storage Systems

When manufacturing facilities use structured storage, there is a significant improvement in the operational efficiency of production facilities. When workers spend less time looking for equipment and materials, they have more time to be productive, which in turn reduces the amount of money spent on labor. It is possible to facilitate speedier staff training and greater cross-functional flexibility by utilizing standardized storage locations.

When storage systems keep walkways and emergency access routes clear, there is a significant improvement in the safety performance of the system. By properly containing the material, slip hazards can be avoided, and the number of accidents can be decreased. As a result of organized storage methods, routine safety checks are able to increase their effectiveness.

Improvements in asset utilization and decreased inventory shrinkage are two factors that contribute to cost control benefits. Utilization patterns can be identified and buying decisions can be optimized with the use of tracking capabilities that are inherent in organized storage systems, such as the White Metal Combination Storage Cabinet. It is possible to extend the lifespan of equipment by ensuring that it is stored in appropriate conditions and protected from environmental degradation.

The implementation of contamination prevention and material tracing systems leads to improvements in quality overall. The integrity of the product is preserved in controlled storage conditions, which also fulfill the standards of quality management systems. Product quality and delivery performance that are consistent with one another lead to increased levels of customer satisfaction.

Conclusion

Manufacturing environments benefit significantly from strategic white metal storage cabinet implementation across diverse applications. Tool organization, PPE management, chemical storage, and documentation protection represent essential uses that improve operational efficiency and safety compliance. These versatile storage solutions adapt to evolving manufacturing requirements while maintaining security and accessibility standards. Investment in quality storage systems generates measurable returns through improved productivity, reduced costs, and enhanced worker safety. Manufacturing facilities that prioritize organized storage create competitive advantages through operational excellence and regulatory compliance.

Frequently Asked Questions

1. What makes white metal storage cabinets suitable for manufacturing environments?

White painted cabinets offer excellent visibility for inventory identification while providing superior corrosion resistance through powder coating processes. The light color reflects ambient lighting, improving visibility in industrial settings. Steel construction withstands heavy use and provides security for valuable tools and materials.

2. How do combination storage systems improve manufacturing efficiency?

Modular storage configurations adapt to changing production requirements without major facility modifications. Workers access multiple storage types from single locations, reducing travel time and improving workflow. Standardized systems enable consistent organization across multiple production areas and facilities.

3. What certifications should manufacturing storage cabinets meet?

Quality storage systems should comply with ISO 9001 manufacturing standards and relevant safety certifications. Environmental compliance through ISO 14001 certification ensures sustainable manufacturing practices. Occupational safety certifications like ISO 45001 verify worker protection capabilities in storage design and implementation.

Partner with Steel art for Premium Manufacturing Storage Solutions

Manufacturing facilities require dependable white metal storage solutions that enhance operational efficiency and worker safety. Steel art specializes in designing and manufacturing premium steel storage systems that meet demanding industrial requirements. Our ISO 9001, ISO 14001, and ISO 45001 certifications guarantee quality standards that exceed international expectations.

Located in Luoyang, China's renowned ancient capital, we leverage advanced manufacturing technologies and optimized supply chain management to deliver exceptional value. Our folding storage innovations provide space-saving transportation and installation benefits that reduce total project costs significantly. Customizable color options from RAL and Pantone charts ensure seamless integration with existing facility aesthetics.

Global manufacturing companies in over 20 countries rely on our expertise for their storage system requirements. Our OEM and ODM capabilities accommodate specific application needs while maintaining consistent quality standards. Whether you need metal storage drawers, industrial cabinets, or complete storage solutions, our experienced team delivers reliable results.

Ready to optimize your manufacturing storage capabilities? Connect with our White Metal Combination Storage Cabinet supplier team to discuss your specific requirements and explore customization options. Our professional consultants provide comprehensive support for project planning and implementation. Contact us at lysteelart@lysteelart.com to begin your storage optimization journey today.

References

1. Johnson, M. & Smith, R. (2024). "Industrial Storage Solutions for Modern Manufacturing." Journal of Manufacturing Systems, 45(3), 78-92.

2. Williams, K. et al. (2023). "Safety Compliance in Manufacturing Storage Systems." Occupational Safety Review, 38(7), 134-148.

3. Chen, L. & Anderson, P. (2024). "Efficiency Improvements Through Organized Manufacturing Storage." Production Management Quarterly, 29(2), 56-71.

4. Thompson, D. (2023). "Chemical Storage Regulations and Best Practices in Manufacturing." Industrial Safety Journal, 41(9), 203-219.

5. Martinez, A. & Brown, S. (2024). "Modular Storage Systems for Lean Manufacturing Implementation." Operations Research Today, 33(4), 87-103.

6. Davis, R. et al. (2023). "Cost-Benefit Analysis of Manufacturing Storage Investments." Industrial Economics Review, 52(6), 245-261.

_1763362969376.webp)